- 您现在的位置:买卖IC网 > Sheet目录1219 > HC5514XEVAL3 (Intersil)EVAL BOARD TI CODEC MOTHER BOARD

�� �

�

�

�Application� Note� 9871�

�The� evaluation� of� all� 9� tests� require� the� following� equipment:�

�a� 600� ?� (1� watt,� 1%)� load,� a� 1777� ?� (2� watt,� 1%)� load,� a�

�26.1k� ?� (1/4� watt,� 1%)� RDC_RAC� resistor,� two� sine� wave�

�generators,� an� AC/DC� volt� meter,� three� external� supplies�

�(V� BH� ,� V� BL� ,� V� CC� ),� a� dual� channel� storage� oscilloscope,� a�

�9.� Con?gured� the� SLIC� in� the� reverse� active� state�

�(C3� =� 1,� C2� =� 1,� C1� =� 0).� Measure� the� supply� currents� and�

�compare� to� those� in� Table� 1.� Repeat� step� 8.�

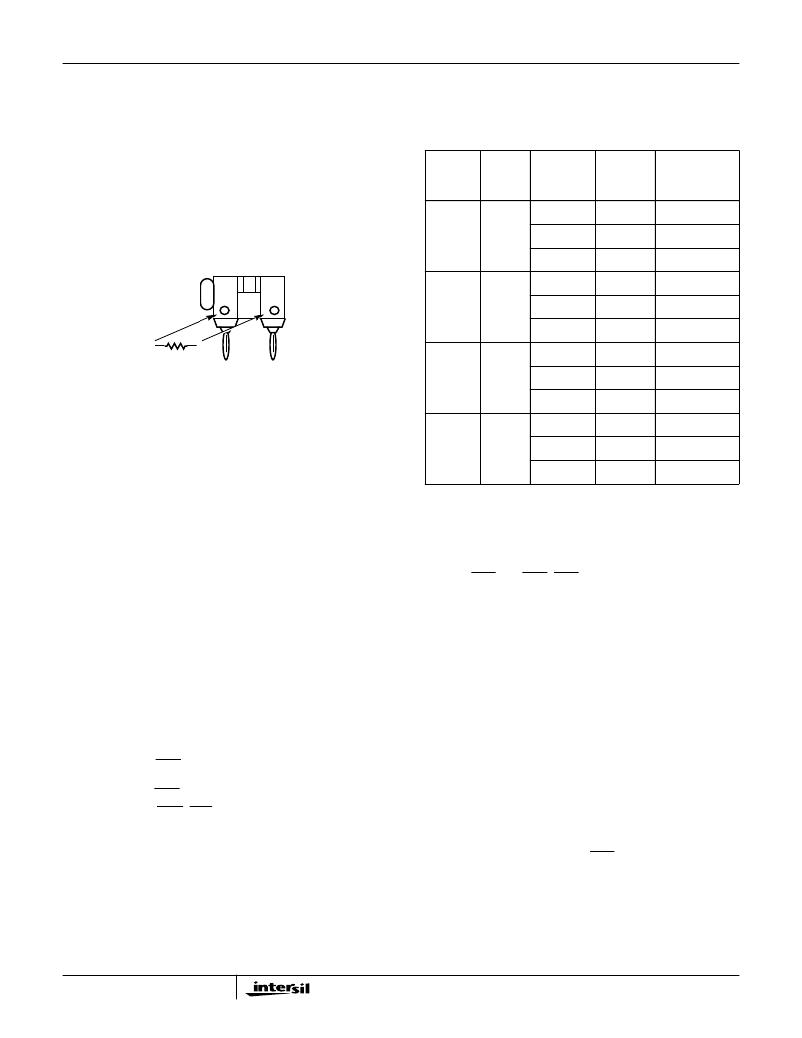

�TABLE� 1.� SUPPLY� CURRENTS� AND� POWER� DISSIPATIONS�

�telephone,� BNC� to� banana� adaptor,� a� battery� backed� AC�

�SUPPLY�

�SUPPLY�

�POWER�

�source� and� a� dynamic� signal� analyzer.�

�LOGIC�

�STATE�

�R� L�

�(� ?� )�

�VOLTAGE�

�(DC)�

�CURRENT�

�TYP� (mA)�

�DISSIPATION�

�(mW)�

�Application� Tip:� When� terminating� tip� and� ring,� it� is� handy� to�

�assemble� terminators� using� a� Pomona� MDP� dual� banana�

�plug� connector� as� the� terminating� resistor� receptacle.� Refer�

�to� Figure� 1� for� details.�

�Forward�

�Active�

�Onhook�

�Without�

�Load�

�V� BH� =� -48V�

�V� BL� =� -24V�

�0.8�

�0.0001�

�38.4�

�0.0024�

�V� CC� =� +5V�

�2.91�

�14.5�

�Forward�

�Offhook�

�V� BH� =� -48V�

�30.0�

�1440�

�A�

�B�

�Active�

�with�

�600� ?�

�V� BL� =� -24V�

�2.68�

�64.3�

�Load�

�V� CC� =� +5V�

�4.2�

�21�

�600� ?�

�Reverse�

�Onhook�

�V� BH� =� -48V�

�0.85�

�40.8�

�Active�

�Without�

�FIGURE� 1.� TERMINATION� ADAPTER�

�Load�

�V� BL� =� -24V�

�V� CC� =� +5V�

�0.0001�

�2.97�

�0.0024�

�14.8�

�Using� the� termination� shown� in� Figure� 1� provides� an�

�unobtrusive� technique� for� terminating� tip� and� ring� while� still�

�providing� access� to� both� signals� using� the� banana� jack�

�feature� of� the� MDP� connector.� Posts� are� also� available� that�

�?t� into� holes� A� and� B,� providing� a� solderable� connection� for�

�Reverse�

�Active�

�Offhook�

�with�

�600� ?�

�Load�

�V� BH� =� -48V�

�V� BL� =� -24V�

�V� CC� =� +5V�

�29.74�

�1.9�

�4.27�

�1427�

�45.6�

�21.3�

�the� terminating� resistor.�

�Test� #1,� Power� Supply� Current� Veri?cation�

�A� quick� check� of� the� evaluation� board� and� sample� is� to�

�measure� the� supply� currents.� The� readings� should� be� similar�

�to� the� values� listed� in� Table� 1.� The� measurements� can� be�

�made� using� a� series� ammeter� on� each� supply,� or� power�

�supplies� with� current� displays.�

�Setup�

�1.� Connect� the� power� supplies� to� the� Evaluation� board.�

�2.� Set� V� BH� to� -48V,� V� BL� to� -24V� and� V� CC� to� +5V.�

�3.� Verify� the� thermal� management� switch� (S9,� located�

�towards� the� top� middle� of� the� board)� is� in� the� V� BL� =� V� BL�

�position.�

�4.� Verify� that� the� POL/REV� switch� S4� (lower� right� hand� side�

�of� the� board)� is� in� either� the� 10ms� or� 20ms� position.�

�5.� Con?gure� the� SHD� switch� (S5)� to� be� in� the� JACK� position.�

�This� will� allow� an� accurate� reading� of� the� V� CC� current� by�

�removing� the� SHD� LED� current.�

�6.� Con?gure� the� GKD_LVM� switch� (S6)� to� be� in� the� BNC�

�position.� This� will� allow� an� accurate� reading� of� the� V� CC�

�current� by� removing� the� GKD_LVM� LED� current.�

�7.� Con?gure� the� SLIC� to� be� in� the� Forward� Active� State�

�(C3� =� 0,� C2� =� 1,� C1� =� 0).� Measure� the� supply� currents� and�

�compare� to� those� in� Table� 1.�

�8.� Terminate� tip� and� ring� with� a� 600� ?� load.� Measure� the�

�supply� currents� and� compare� to� those� in� Table� 1.� Remove�

�600� ?� load.�

�2�

�Test� #2,� Normal� Loop� Feed� Veri?cation�

�This� test� veri?es� the� correct� tip� and� ring� voltages� in� both�

�onhook� and� offhook� forward� active� and� reverse� active� states.�

�Loop� current� and� ground� key� detect� are� also� veri?ed� via� the�

�onboard� SHD� and� GKD_LVM� LEDs.�

�Discussion�

�The� HC5514� is� designed� to� have� its� most� positive� 2-wire�

�terminal� (tip� in� the� forward� active� state� and� ring� in� the�

�reverse� active� state)� ?xed� at� a� set� voltage.� This� set� voltage�

�depends� upon� the� required� overheads� for� the� application.�

�The� most� negative� 2-wire� terminals� voltage� is� dependent�

�upon� the� load� across� tip� and� ring� and� the� programmable�

�current� limit.�

�The� tip� and� ring� voltages� for� various� loop� resistances� are�

�shown� in� Figure� 2.� The� tip� voltage� remains� relatively�

�constant� as� the� ring� voltage� moves� to� limit� the� loop� current�

�for� short� loops.�

�When� power� is� applied� to� the� SLIC,� a� loop� current� will� ?ow�

�from� tip� to� ring� through� the� 600� ?� load.� Loop� current�

�detection� occurs� when� this� loop� current� triggers� an� internal�

�detector� that� pulls� the� output� of� SHD� low,� illuminating� the�

�LED� through� the� +5V� supply.�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

HC55185EVAL2

EVALUATION PLATFORM HC55185+T

HE1015

BOOT CIRCUIT BREAKER 1POLE CLEAR

HE1020

BOOT CIRCUIT BREAKER 2POLE CLEAR

HE1050

BOOT CIRCUIT BREAKER 3POLE CLEAR

HE1070

BOOT CIRCUIT BREAKER 3POLE CLEAR

HFW30R-1STE1

HFW30R-1STE1-FFC/FPC CONN

HFW30S-2STE1

HFW30S-2STE1-USING HFW-P5SL

HHG

FUSEHOLDER AUTO INLINE FOR ATC

相关代理商/技术参数

HC5515

制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:ITU CO/PABX SLIC with Low Power Standby

HC5515_06

制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:ITU CO/PABX SLIC with Low Power Standby

HC55150

制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:Low Power Universal SLIC Family

HC55150CB

制造商:Rochester Electronics LLC 功能描述:LOW PWR SLIC,POL REV/METERING,55DB BALANCE - Bulk

HC55150CBZ

功能描述:电信线路管理 IC LW PWR SLIC POLV/MTRING 55DB RoHS:否 制造商:STMicroelectronics 产品:PHY 接口类型:UART 电源电压-最大:18 V 电源电压-最小:8 V 电源电流:30 mA 最大工作温度:+ 85 C 最小工作温度:- 40 C 安装风格:SMD/SMT 封装 / 箱体:VFQFPN-48 封装:Tray

HC55150CM

制造商:Rochester Electronics LLC 功能描述:LOW PWR SLIC,POL REV/METERING,55DB BALANCE - Bulk

HC55150CMZ

功能描述:电信线路管理 IC LW PWR SLIC POLV/MTRING 55DB RoHS:否 制造商:STMicroelectronics 产品:PHY 接口类型:UART 电源电压-最大:18 V 电源电压-最小:8 V 电源电流:30 mA 最大工作温度:+ 85 C 最小工作温度:- 40 C 安装风格:SMD/SMT 封装 / 箱体:VFQFPN-48 封装:Tray

HC55151

制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:Low Power Universal SLIC Family